| Item Code |

|||||

| 6bar. | TCFMVDX0300LFD | TCFMVDX0400LFD | TCFMVDX0500LFD | TCFMVDX0800LFD | TCFMVDX1000LFD |

| Multi Energy | 300 | 400 | 500 | 800 | 1000 |

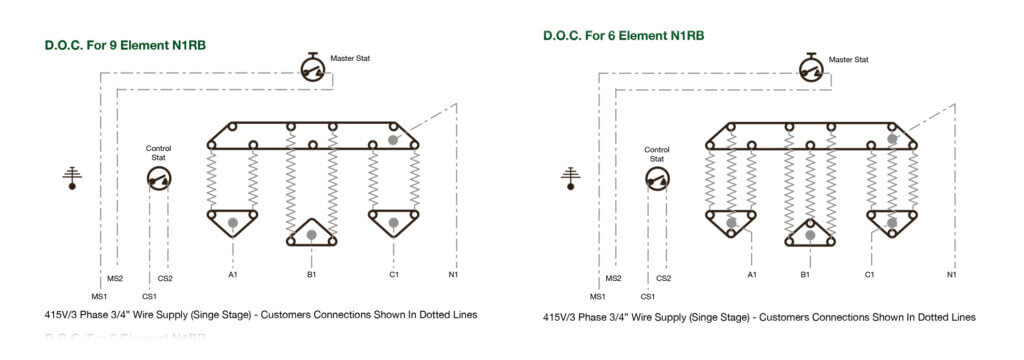

| Titanium Imm. – Fact. Fitted As Std. | 3 x 6kW | 3 x 6kW | 3 x 6kW | 3 x 6kW | 2 x 6kW |

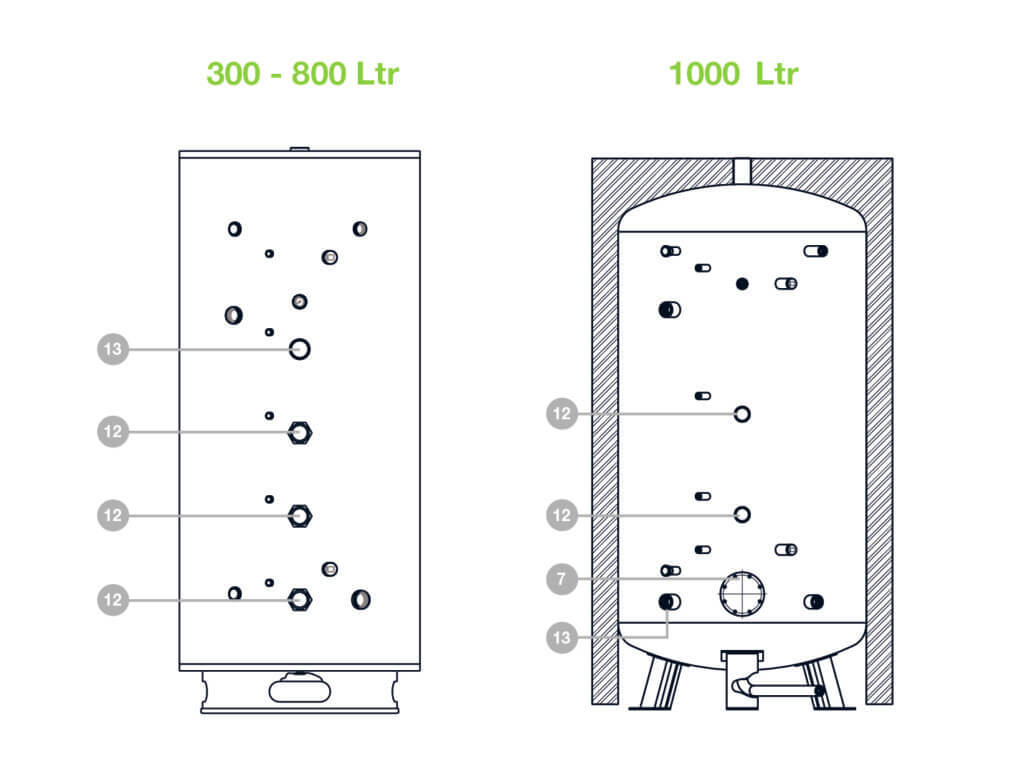

| No. Of Imm Heater Bosses In Total | 4x Screw | 3x Screw + 1x Flange | |||

| Maximum Energy Input Permitted (kW) | 48 | 48 | 48 | 48 | 78 |

| Inspection Flange | Optional – CANNOT be used for flanged imm. heaters | Supplied as std – CAN be used for fl. imm. | |||

| Heat Up Time ΔT 50°C | Reheat time in mins = Litres x 3.2 / kW installed | ||||

| All Cylinders – 3 & 6 bar | 300 | 400 | 500 | 800 | 1000 |

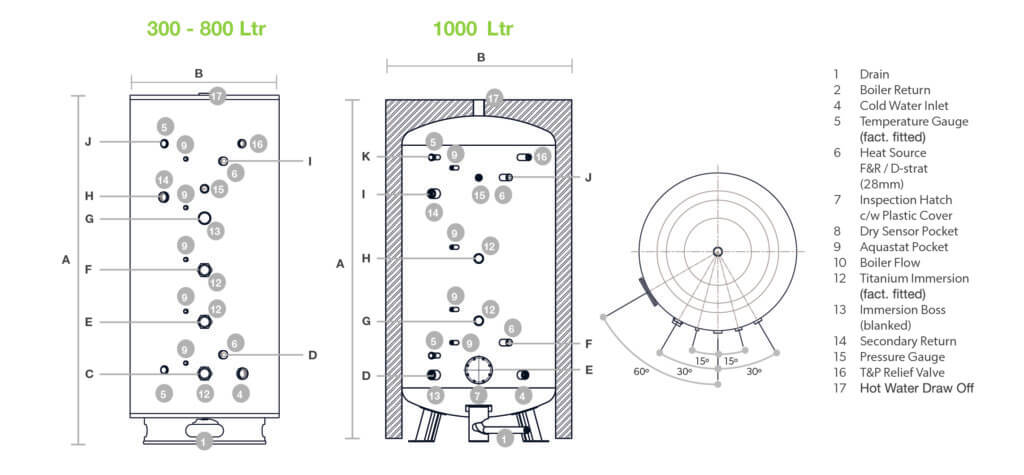

| Diameter (mm) | 620 | 710 | 710 | 920 | 1100 |

| Height (mm) | 1670 | 1670 | 2030 | 2050 | 2170 |

| Hot And Cold Connections BSP F | 1.5” | 1.5” | 1.5” | 2.0” | 2.0” |

| Coil Conn. (+for the solar coil) BSP F | 1.5” | 1.5” | 1.5” | 1.5” | 1.5” |

| Secondary Return BSP F | 1.25” | 1.25” | 1.25” | 1.25” | 1.25” |

| Max. Op. Pressure – 3/6 bar kit (bar) | 6 / 10 | 6 / 10 | 6 / 10 | 6 / 10 | 6 / 10 |

| T&P Setting 3/6 bar kit (bar) | 7 / 10 | 7 / 10 | 7 / 10 | 7 / 10 | 7 / 10 |

| T&P Size – Multi Energy / Indirect+Solar | 1.0” / 0.75” | 1.0” / 0.75” | 1.0” / 0.75” | 1.0” / 0.75” | 1.25” / 0.75” |

| Cold W. Safety Devices – PRV, ERV, Chk Vlv | 1.0” (one piece) | 1.25” (multi-piece) | |||

| Exp. Relief Valve Setting – 3/6 bar kit (bar) | 6 / 8 | 6 / 8 | 6 / 8 | 6 / 8 | 6 / 8 |

| 2-port Mot. Valve (Indirect & Solar Only) | 28mm | 28mm | 28mm | 28mm | 1.25” |

| 2-port Mot. Valve Conn. (Ind & Sol Only) | Compression nut and olive | Pipe union conn. nut and tail piece | |||

| Expansion Vessel Size – 3/6 bar kit (ltr) | 24 / 35 | 35 / 50 | 50 / 80 | 80 / 100 | 100 / 150 |

| Tundish | 1.25” | 1.25” | 1.25” | 1.25” | 1.5” |

| ErP Energy Efficiency Class | C | C | C | C | C |

| Standing Loss (W) | 92 | 102 | 115 | 121 | 124 |

| Performance | 300 | 400 | 500 | 800 | 1000 | |

| Hot Water Capacity (ltr) | 289.5 | 391 | 497 | 766 | 1097 | |

| Quantity Of Factory Fitted Immersions | 3 | 3 | 3 | 3 | 2 | |

| Rating Of Factory Fitted Imm. (kW/V) | 6/240 | 6/240 | 6/240 | 6/240 | 6/240 | |

| Factory Fitted Immersion Type | Titanium | |||||

| Number Of Immersion Bosses | 4 | 4 | 4 | 4 | 2 | |

| Max. Allowable Power Outp. Of Imm. (kW) | 48 | 48 | 48 | 48 | 78 | |

| Inspection Flange | Optional | Standard | ||||

| Heat Up Time (ΔT 50°C) | min | 53 | 71 | 89 | 143 | * |

| Fact. Fitted | kW | 18 | 18 | 18 | 18 | 12 |

| Cont. Output – Fact. Fitted | L/hr | 281 | 281 | 281 | 281 | * |

| Heat Up Time (ΔT 50°C) | min | 21 | 29 | 37 | 57 | 49 |

| Max. Allowed | kW | 48 | 48 | 48 | 48 | 78 |

| Cont. Output @60ºC – Max. Allowed | L/hr | 826 | 826 | 826 | 826 | 1342 |

| Weight Empty (kg) | 71.5 | 72 | 89 | 186 | 188 | |

| Weight Full (kg) | 361 | 463 | 586 | 952 | 1285 | |